Understanding the Importance of Yard Capacity in Logistics

Understanding Yard Capacity

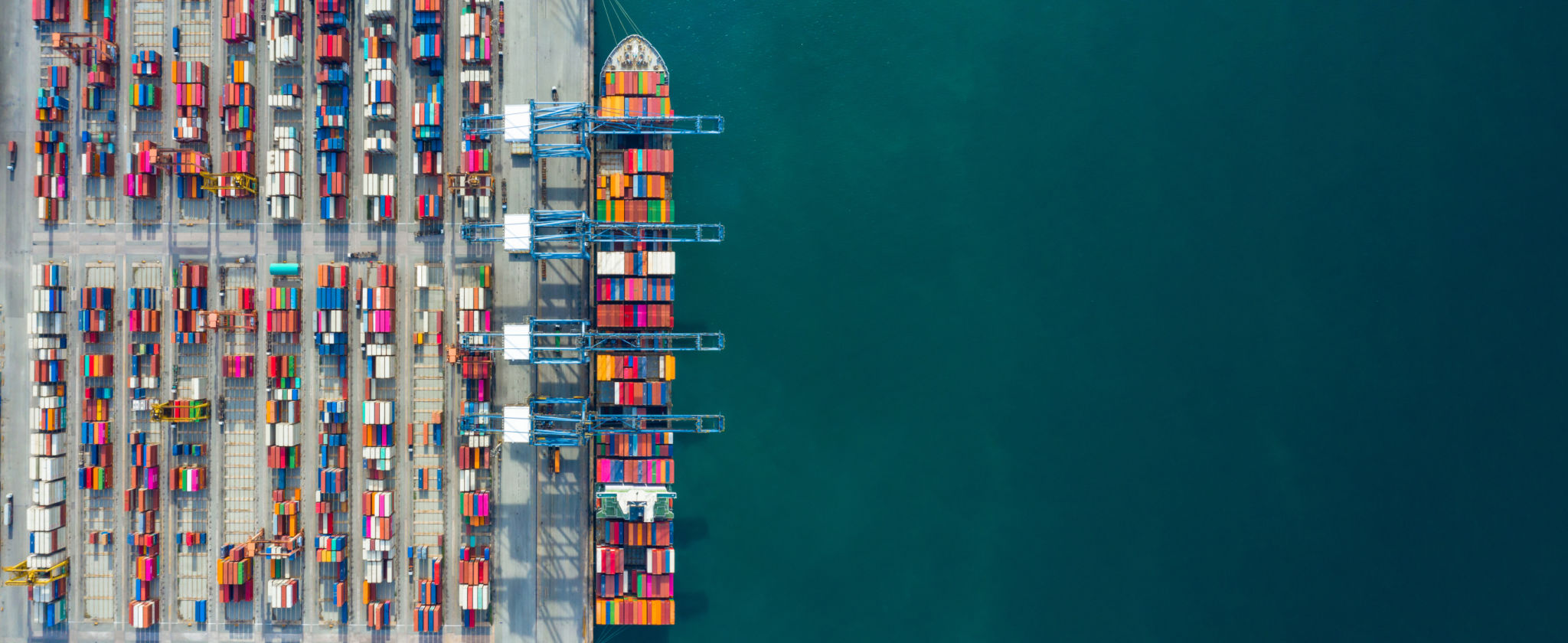

In the logistics industry, the term "yard capacity" is pivotal yet often overlooked. It refers to the ability of a facility's yard to accommodate vehicles, containers, and cargo. Maximizing yard capacity ensures smooth operations, reducing delays and enhancing overall efficiency. A yard that is well-managed and utilized can significantly impact the supply chain's performance.

Adequate yard capacity prevents bottlenecks, allowing for timely loading and unloading of goods. This capability is crucial during peak seasons when the flow of merchandise increases, demanding an efficient system to handle the surge. Companies that fail to optimize their yard capacity may experience delays, increased operational costs, and dissatisfied clients.

Factors Affecting Yard Capacity

Several factors influence yard capacity, making it essential for logistics managers to understand and manage them effectively. These factors include the physical dimensions of the yard, the layout, and the type of vehicles and containers used. Proper planning and management of these elements can maximize space and improve traffic flow within the yard.

Additionally, technological advancements like automated gate systems and real-time tracking solutions can further enhance yard capacity. Implementing these technologies allows for better scheduling, reducing turnaround times and preventing congestion. As logistics operations become more complex, technology plays a crucial role in managing yard efficiency.

The Role of Technology in Yard Management

Technology has revolutionized how yards are managed in the logistics industry. By using tools such as yard management systems (YMS), companies can track and optimize their yard operations in real-time. These systems provide insights into yard activities, helping managers make informed decisions that enhance productivity.

Automated systems can schedule arrivals and departures more effectively, ensuring that there is no overlap or congestion. This level of control minimizes idle times and maximizes yard throughput. Furthermore, technology aids in predictive analysis, allowing companies to anticipate demand changes and adjust their yard capacity accordingly.

Benefits of Optimizing Yard Capacity

Optimizing yard capacity offers several benefits that directly impact a company's bottom line. An efficient yard reduces wait times for drivers, leading to increased satisfaction and reduced fuel consumption. Additionally, it minimizes demurrage charges, which can be costly when containers are held longer than planned.

Moreover, an optimized yard enhances safety by reducing the likelihood of accidents caused by congestion or improper vehicle movements. It also improves inventory management, as goods can be processed faster and more accurately. These advantages contribute to a more streamlined operation, enabling companies to meet customer demands promptly.

Strategies for Improving Yard Capacity

There are several strategies that logistics companies can employ to improve their yard capacity. Regularly reviewing and updating yard layouts can ensure that space is used effectively. Implementing a robust YMS can provide valuable data insights and automate scheduling processes.

Training staff on efficient yard operations is also crucial. Well-trained personnel can make quick decisions that prevent delays and maintain smooth operations. Furthermore, fostering a culture of continuous improvement encourages innovation and adaptation to new technologies or processes that enhance yard capacity.